Our SMT machines

|

JTR Series

Collect

Product parameters

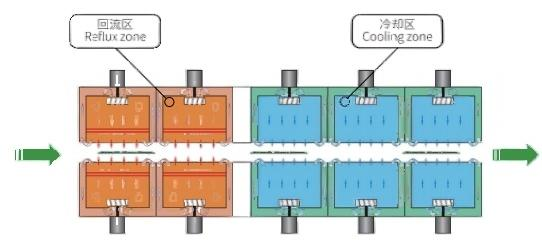

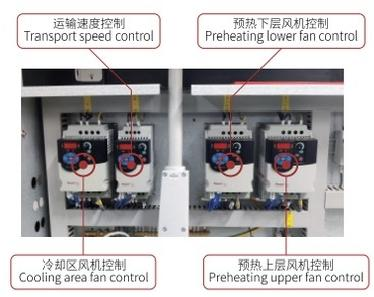

JTR series lead-free hot-air reflow parameters

Product Description

JTR series lead-free hot-airreflow soldering machine

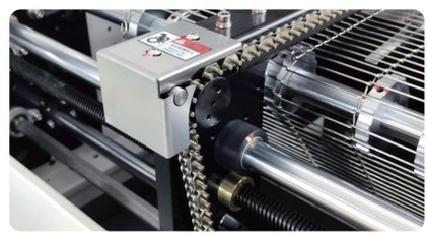

Double-row stainless steel chain

Cooling capacity improvement · The cooling slope is increased by25%,and the PCB output temperature is reduced by 30%.

Stainless steel transport chain Double-row stainless steel transport chain. The welding temperature of PCB edge parts is not affected by the heat absorption of guide rail, ensuring perfect welding quality.

Temperature stability 8mm thick thermal storage aluminum plate ensures stable Temperature in mass production.

Rapid warming · The heating time of reflow soldering is shortened by 30%, and it can be put into production quickly

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||