Our SMT machines

|

KT Series

Collect

Product parameters

KT series high-end lead-free hot-air reflow parameters

Product Description

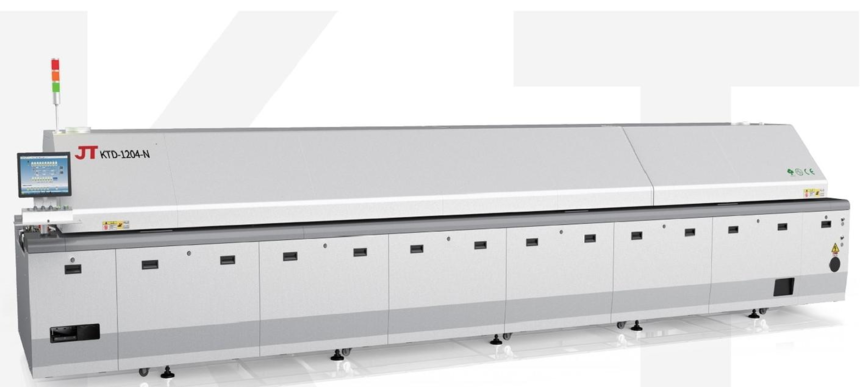

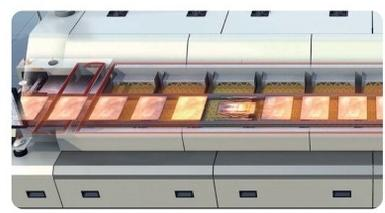

KT series high-end lead-free hot-air reflow soldering machine

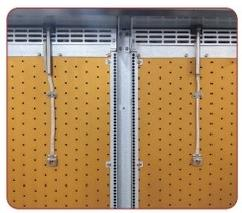

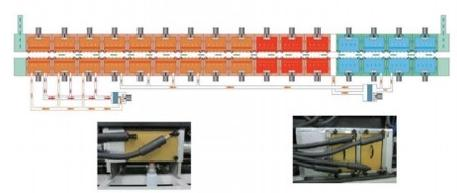

Sampling port for whole-process oxygen concentration inspection

Nitrogen System

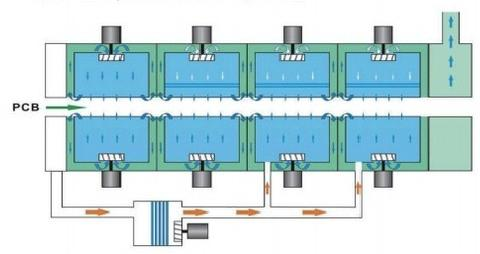

Independent detection of oxygen concentration in the whole process 1.The nitrogen quantity in the whole process can be controlled,and each temperature zone can be controlled in an independent closed loop,so that the oxygen concentration range can be controlled within 50-200ppm. 2.When the oxygen concentration in the whole process is within 200ppm the nitrogen consumption is:22-25m3/H(12 temperature zone); 3.When the oxygen concentration in the welding area is within 1000ppm, the nitrogen consumption is 10-12m³/H(12 temperature zone).

Practical significance of whole-process hypoxia concentration control 1.Inert protection shall be provided throughout the process to prevent secondary oxidation of the welding interface;Poor wetting caused by oxidation will lead to more fatal hazards in the process of miniaturization and close spacing. 2.Increase the width of lead-free welding process window and make process commissioning more flexible;In nitrogen environment,the surface tension of liquid solder decreases,which can effectively reduce the peak temperature and shorten the reflow time

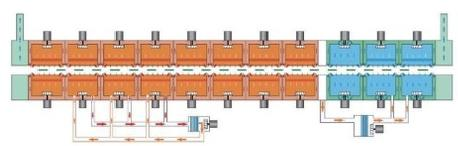

Recovery System Principle of staged recovery 1.Make use of the physical characteristics of the flux to scientifically recover the volatile organic matter of the flux.

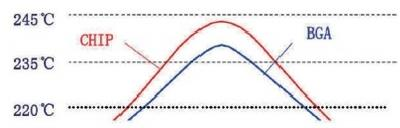

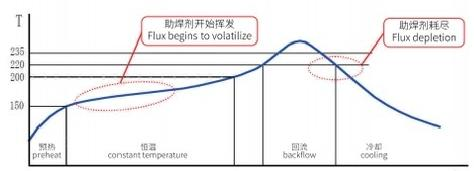

Time-temperature profile Recovery design of bottom exhaust port 1.Avoid the amount of flux drops caused by the accumulation of flux at the exhaust port.

Preheating module

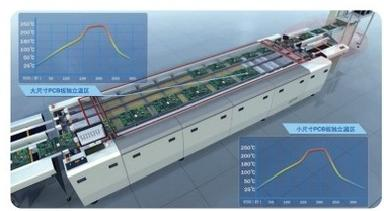

Eficient heating capacity At the same time,when welding components with large differences in size,the reflow oven equipment is required to maintain high thermal efficiency at low convection wind speed

High capacity High productivity, production chain speed up to 160cm/min:Low energy Consumption,new thermal management system, effectively reducing costs;specializing in high-speed production and high-precision PCB packaging process.

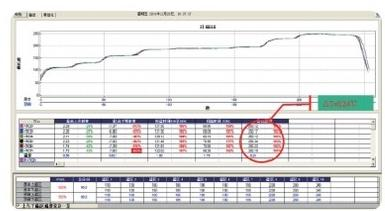

Excellent temperature control ability Strong temperature control ability,high temperature control accuracy,and the temperature difference between the setting and the actual temperature is within 1.0℃; Temperature fluctuation from unload to full load is within 1.5°℃;The temperature difference between adjacent temperature is within 100℃due to the super fast temperature rise and fall capability

Fast thermal recovery capability The precise PID temperature control and high heat specific capacity furnace cavity structure design make KT series have excellent fast thermal compensation capability The furnace temperature fluctuation of KT series fast thermal compensation system is≤1.5℃under unload and full-load conditions.

Excellent cooling capacity

Multizone double-sided cooling ·It is applicable to PCB products with large thermal capacity to ensure low product outlet temperature.

Transportation System

Transport control unit Servo motion drive system,accurate speed and smooth transportation

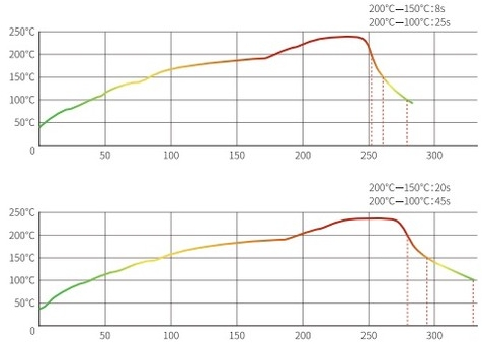

Comparison with traditional one-sided cooling profile

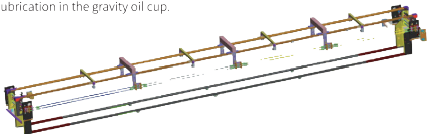

Guide rail width adjusting unit 1.Guide rail width adjustment drive adopts rigid shaft rotation to ensure the synchronization of front and rear width adjustment; 2.In the direction of rail transportation, 5 sets of synchronous screw are adopted to solve the problems of board jamming and falling in the furnaces 3.The adjustable and stabilized oil pump is used to solve the problem of uneven lubrication in the gravity oil cup.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||