Our SMT machines

|

GAM320AT

Collect

Product parameters

Specifications

Product Description

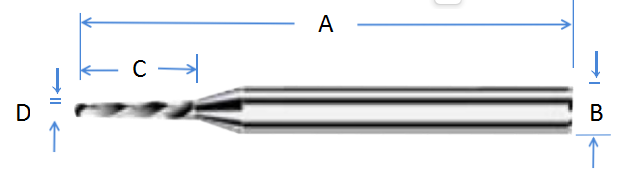

Special Milling Bit

Milling bit size Ø 0.8 ~ Ø3.0 mm

Right and left rotation; Lower cut; Carbon alloy milling bit head Total Length (A): 38.1 ±0.30 mm Diameter (B): 3.175 mm Cutting Length (C): 6 ±0.50 mm (Depending on the diameter of the milling bit, the length of the milling bit) Cutting Dia. (D): 0.8 、 1.0 、 1.2 、 1.5 、 1.6 、 1.8 、 2.0 、2.4 、3.0 mm Special&Customized Fixture

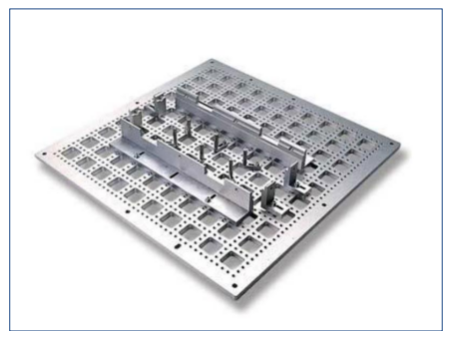

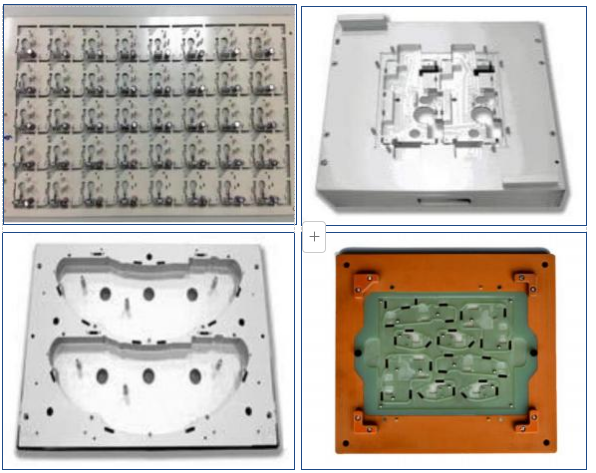

Universal Fixture Used for verious size and any shape of PCBs.

Customized Fixture High precision cutting and stable.

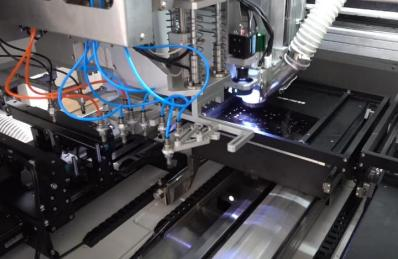

Machine Configuration - S pe ical Function

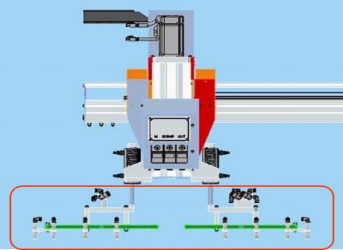

1、Automatically adjust the width of the board to receive the PCB board Elastic clamping edge, auxiliary positioning.

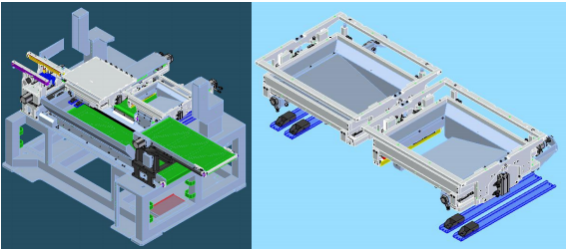

2、 Provide dual worktables for placing and cutting PCB in parallel to enhance the efficiency of operation.

3、 Optimize the inlet and outlet nozzles, wide applicability-the nozzle takes and discharges the material Other Function

4、 Patent Flexible Cleaning Brush Module Reduce milling bit loss and improve dust collection effect; When the milling it is used for segmental cutting, the resistance of the Z axis during cutting can be reduced, and the milling bit can be used more effectively.

5、 Install the Cover Module Mechanism. Reduce dust pollution to PCBA parts during boards separtion.。

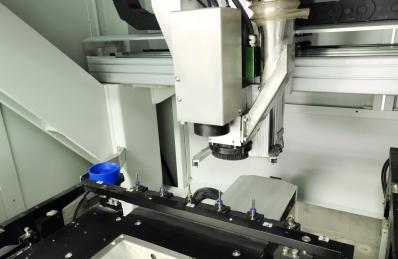

6、Auto-Tool Change Function It prevent work injuries and misoperation. Adopt German imported spindle, with low cutting stress, smooth edge and high precision. The Z axis has an automatic compensation setting, which can automatically adjust the depth of the milling cutter. In the future, the signal port of the robotic arm can be expanded for free to realize unmanned operation.

7、The feeding arm is changed to a modular design,and the feeding and discharging modules can be selected customer needs.When changing the line,the Inlet/outlet nozzle module can be quickly replaced,which shortens the line change time by more than 50%.

8、 Suction simulation setting to avoid board dropping

9、Auto Open/Close switching module for clamp plate. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||