Our SMT machines

|

GAM320A

Collect

Product parameters

Specification

Product Description

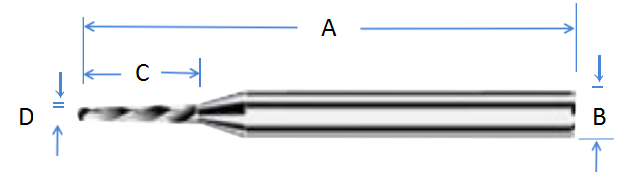

Special Milling Bit

Milling bit size Ø 0.8 ~ Ø3.0 mm

Right and left rotation; Lower cut; Carbon alloy milling bit head Total Length (A): 38.1 ¡À0.30 mm Diameter (B): 3.175 mm Cutting Length (C): 6 ¡À0.50 mm (Depending on the diameter of the milling bit, the length of the milling bit) Cutting Dia. (D): 0.8 ¡¢ 1.0 ¡¢ 1.2 ¡¢ 1.5 ¡¢ 1.6 ¡¢ 1.8 ¡¢ 2.0 ¡¢2.4 ¡¢3.0 mm Special&Customized Fixture

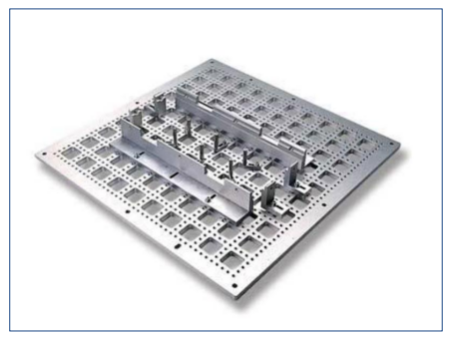

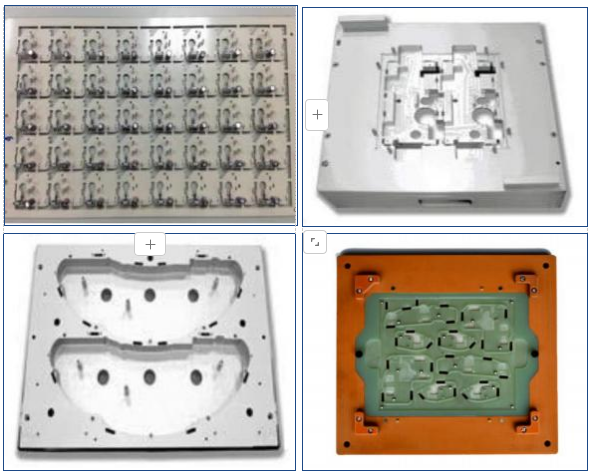

Universal Fixture Used for verious size and any shape of PCBs.

Customized Fixture High precision cutting and stable. Machine Configuration

Offline Automatic PCB Separator 1. Adopts Panasonic Servo Controller, SMC pneumatic components, TBI screw, PMI Guide rail and Delta PLC control system. 2. It can be read by the handheld barcode machine and managed by the Central MES (Manufacturing Execution System) via Ethernet. 3. Dual worktables can simultaneously cut and place PCB, reducing the waiting time for placing workpieces. 4 . The dual work table can be combined into a single large worktable (700*300mm) to extend the size of the cutting area, which is suitable for cutting large-sized PCBA.

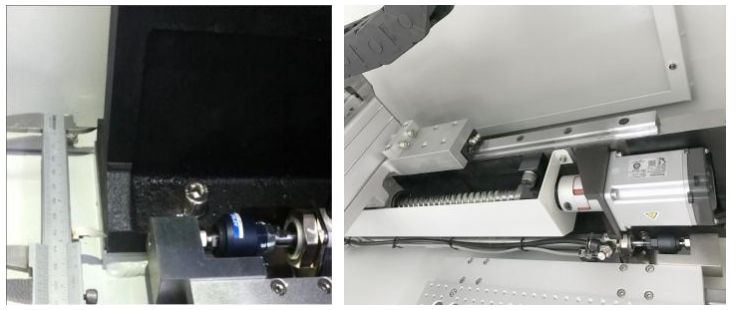

Vacuum Damper Integrated Design Adopts Japan SMC cylinder drive, which is stable and reliable. It switches quickly with low wind noise which fully guarantees the dust-absorbing effect.

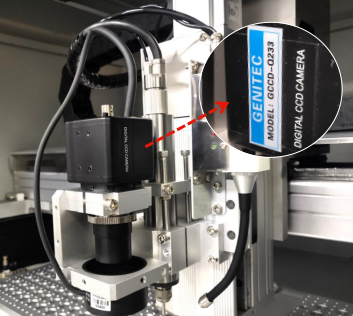

Taiwan Genitec CCD Camera 1. The LED iris automatically adjusts the light, and the brightness can be adjusted by software control. 2. The cutter diameter can be entered directly. 3. The image is combined with the operation screen for easy teaching and input; 4. The image is directly captured from the workpiece and magnified 15 times to improve the accuracy of the teaching. 5. The cross mark has a round frame and a quad frame, which can be arbitrarily set. Machine Configuration

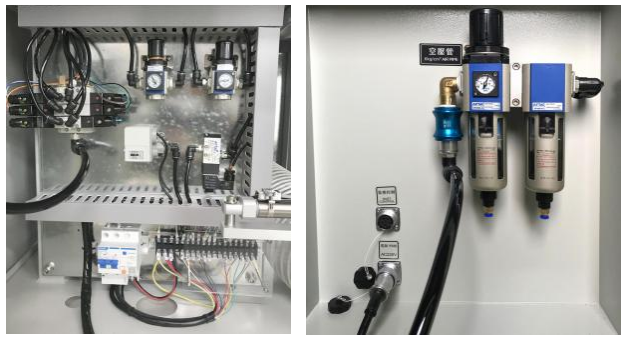

Air Part 1. The intake air adopts 40u+10u two-stage filtration and automatic drainage to ensure the cleanness of the air source to prolong the life of the pneumatic components, and the cooling of the main shaft cooling gas source and extend the service life of the main shaft. 2. Adopts Taiwan AIRTAC magnetic valve.

Power Control 1. Adopts the simple maintenance integrated module board. The acrylic protection cover of the wiring terminal is in compliance with safety regulations. 2. All signal lines have line codes. It's easy to maintain because when the machine fails, corresponding codes will appear. 3. Adopts Japanese Panasonic servo. Machine Configuration

X.Y.Z Support Base Adopts mold forming and triangular electric tower design. The fixed width of the base is 80mm, which is stable.

Axis Card 1. Adopts Taiwan ICP, DAS axis card. 2. Axis control card adopts high-speed integrated CPU&GPU, which runs stably, and responds quickly and takes up less system resources. |