Our SMT machines

|

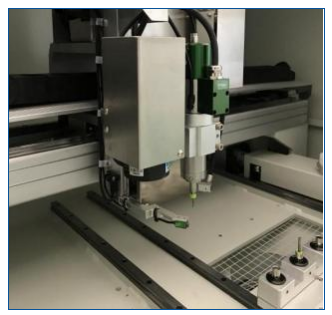

GAM330

Collect

Product parameters

Specification

Product Description

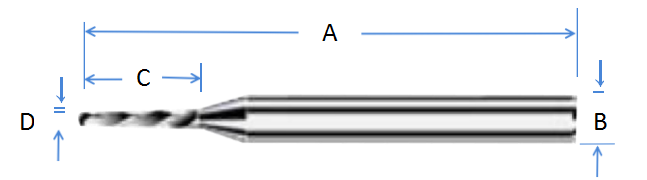

Special Milling Bit

Milling bit size Ø 0.8 ~ Ø3.0 mm

Right and left rotation; Lower cut; Carbon alloy milling bit head Total Length (A): 38.1 ¡À0.30 mm Diameter (B): 3.175 mm Cutting Length (C): 6 ¡À0.50 mm (Depending on the diameter of the milling bit, the length of the milling bit) Cutting Dia. (D): 0.8 ¡¢ 1.0 ¡¢ 1.2 ¡¢ 1.5 ¡¢ 1.6 ¡¢ 1.8 ¡¢ 2.0 ¡¢2.4 ¡¢3.0 mm Special&Customized Fixture

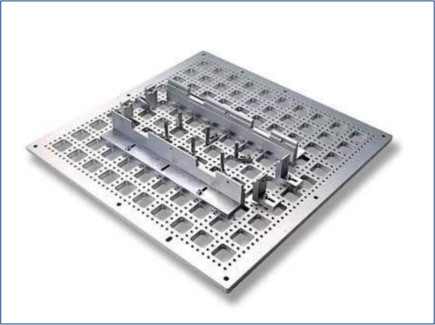

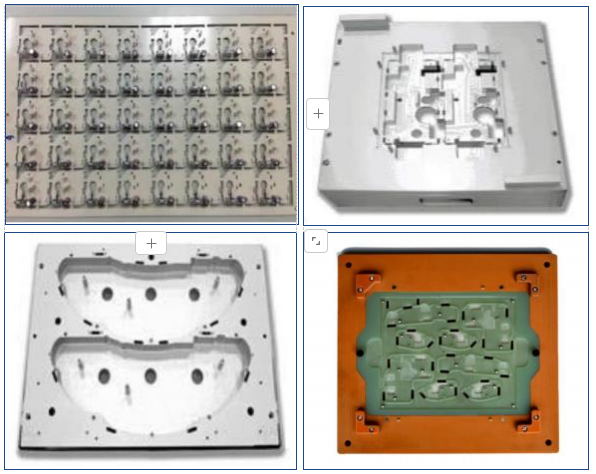

Universal Fixture Used for verious size and any shape of PCBs.

Customized Fixture High precision cutting and stable. Hardware Introduction

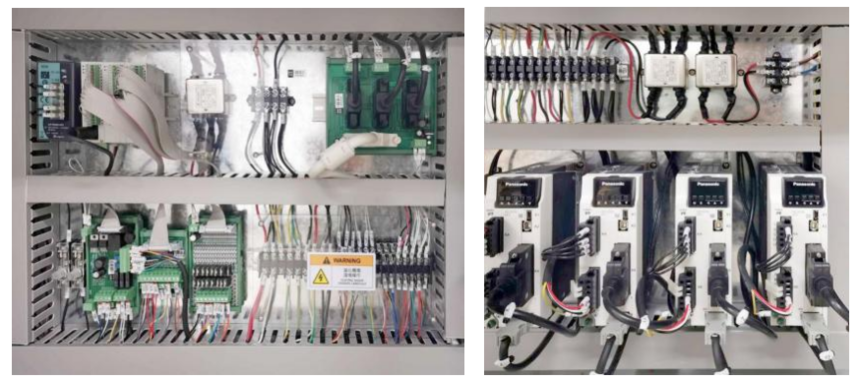

1.Power Control the entire electronic control is in the front section of the machine, simple and clear, and with the operation manual troubleshooting list. Systematic assembly greatly reduces the difficulty of maintenance. Hardware Introduction

2.Dust Collectio Vacuuming and cutting single-sided slabs are synchronized, using Japanese SMC cylinders ,it is move stable and reliable, fully ensuring vacuuming effect.

3.Auto tool change Has auto tool change function to prevent work injuries and mistakes. Adopts Germany spindle, the cutting stress is small, the edge of the board is smooth, and the cutting precision is high. The Z axis has an automatic compensation setting that automatically adjusts the depth of the milling cutter. In the future, the robot arm signal port can be extended free of charge for unmanned operation. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||