Our SMT machines

|

BC660C

Collect

Product Description

PCBA In line Cleaning System Technical SPEC System name:PCBA In line Cleaning System Model:BC660C 1.BC660C PCBA In line Cleaning System Structure and SPEC

1.1 BC660C Structure and specification

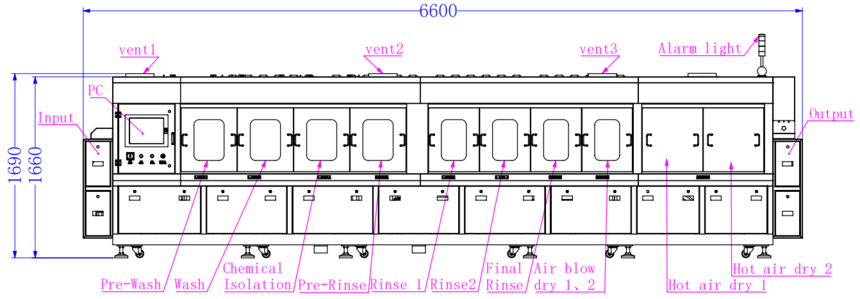

System front view

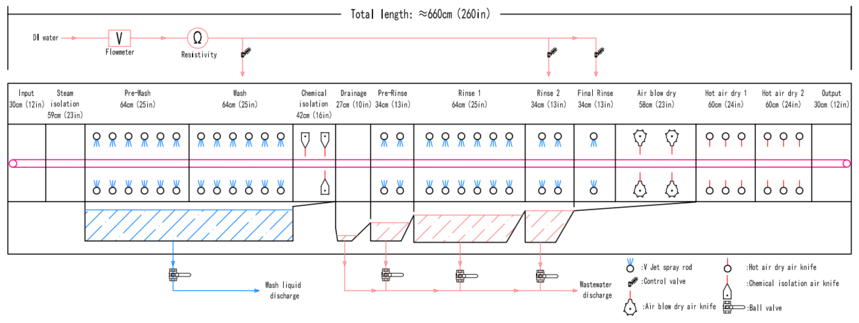

Spray manifolds, air knives, liquid tank, water tank, water inlet, drainage configuration diagram 1.2 System Working principle and SPEC

1.21 Mainly application:

System Mainly used to clean flux residual and solder balls on the PCBA after PCBA assembly soldering. The system adopts high pressure and high flow spray cleaning process to wash,rinse and dry PCBA(substrate) automatically.

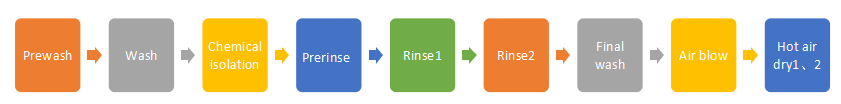

1.22 Wash flow process:

Put in PCBA → Chemical liquid pre-wash → Chemical liquid wash →Chemical isolation → DI water pre-rinse → DI water rinse1 →DI water rinse2 →DI water final spray rinse → Air blow → Hot air dry 1 → Hot air dry 2 → send out PCBA

1. Pre-wash section: Soften and decrease the biscosity of flux or dusts. 2. Wash section: Wash flux and dusts particles on PCBA. 3. Chemical isolation section: Isolation liquid between wash and DI water pre-rinse section. 4. Pre-rinse section: DI water spray to take off liquid on PCBA. 5. Rinse1 section: DI water further spray to take off liquid and ion contamination on PCBA. 6. Rinse2 section: DI water further spray to take off liquid and ion contamination on PCBA. 7. Final rinse section: Fresh DI water spray to take more ion contamination on PCBA. 8. Air blow section: Blow off DI water on PCBA. 9. Hot air dry section: Hot air blow to make moisture on PCBA into vapor and make it dry.

1.3 System Technical Specifications

|